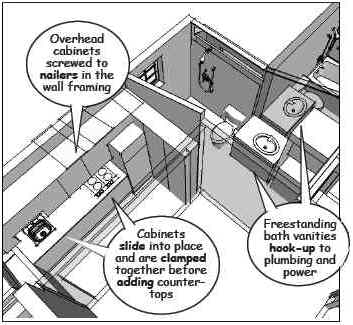

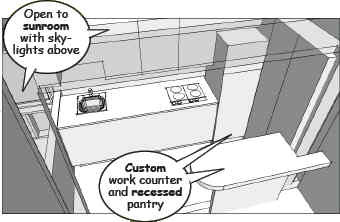

Most residential kitchens and bath cabinets are modular units, prefabricated assemblies, built to match standard cabinet dimensions and installed by finis carpenters.

Kitchen and bath planners

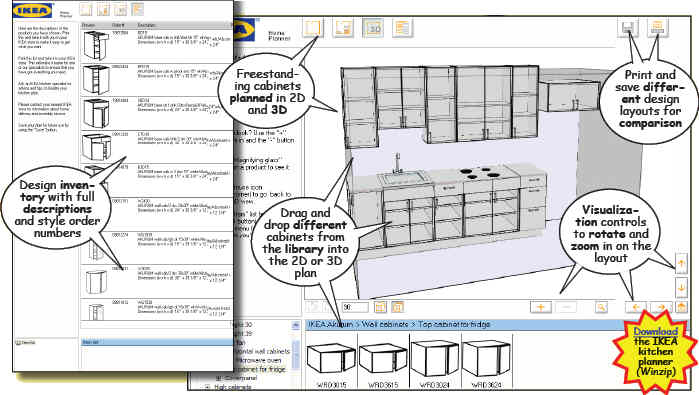

Modular units are laid out using kitchen and bath planners available online. These include online planners from the big box stores like Home Depot and Lowes, as well as websites like CliqStudios or National Kitchen and Bath Association.

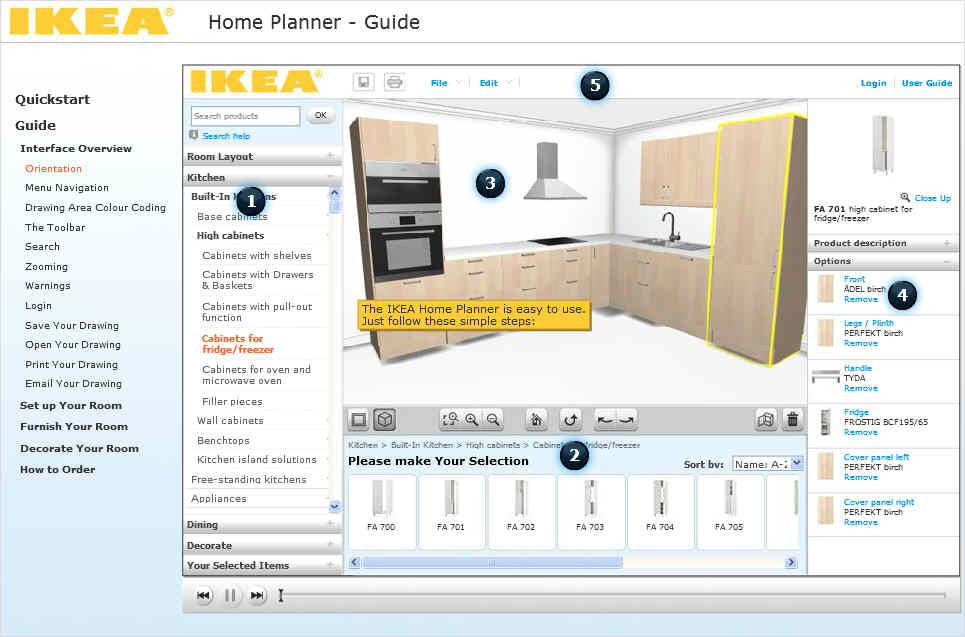

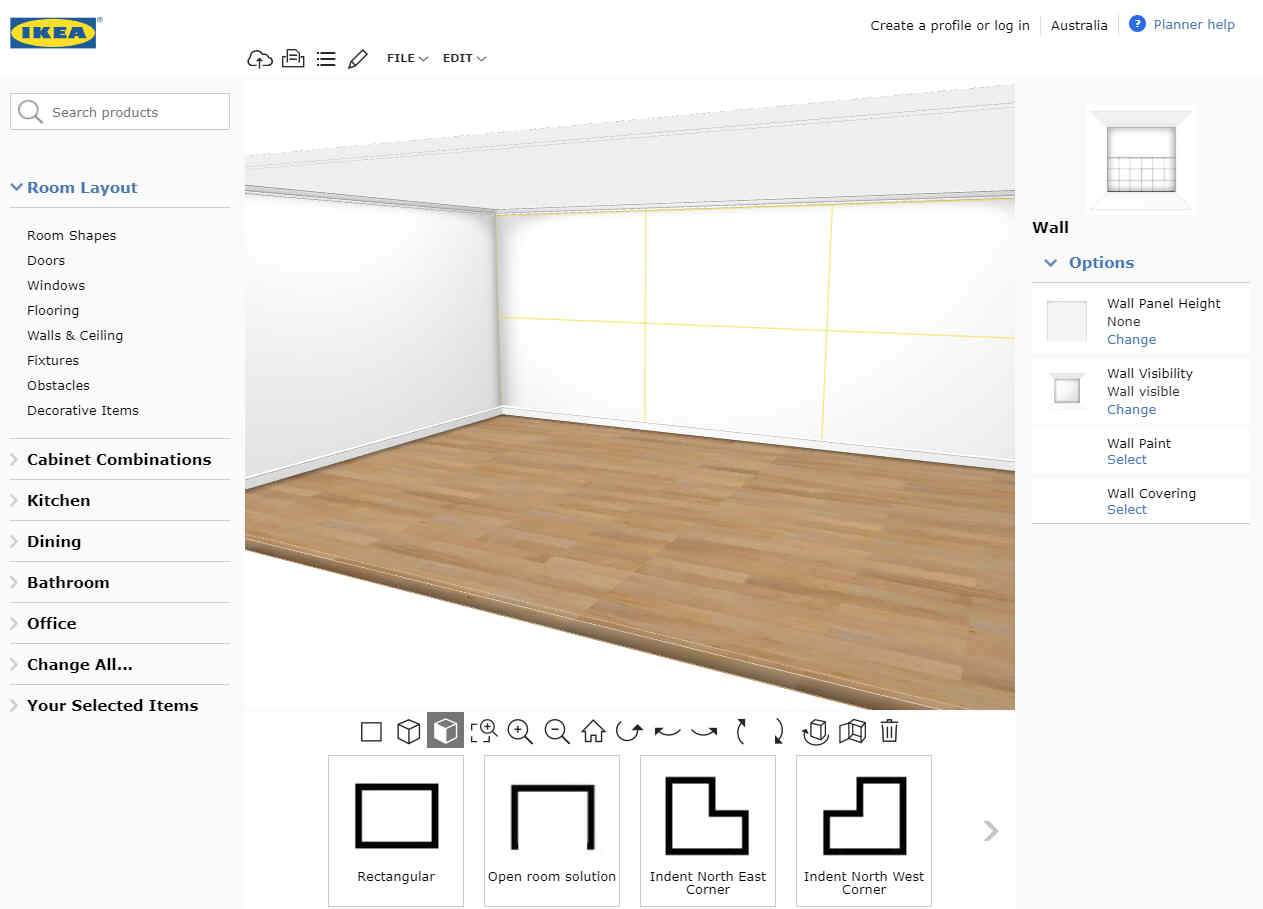

By far, the easiest and most intuitive cabinet design tool is the one offered by IKEA. To aid customers, the company publishes Quick Start and Guide videos that make the kitchen and bathroom planning process completely intuitive.

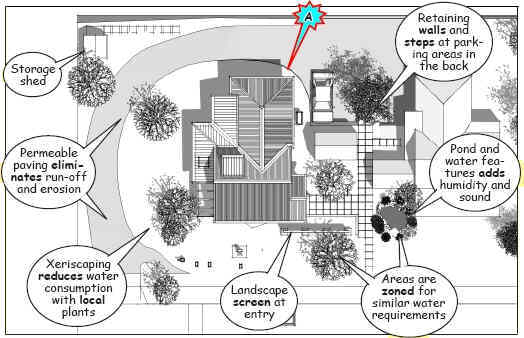

The Ikea planner uses a two and three dimensional graphic interface to visually guide the design. There are icons and menus to locate doors, windows, plumbing, electrical, and other features that need to be incorporated into the final layout. (Millimeter to feet converter).

The planner also keeps a running inventory, along with the cost of the cabinets, to make it easier to order the cabinets (from any supplier). Plans and specifications can also be printed to guide the installation.

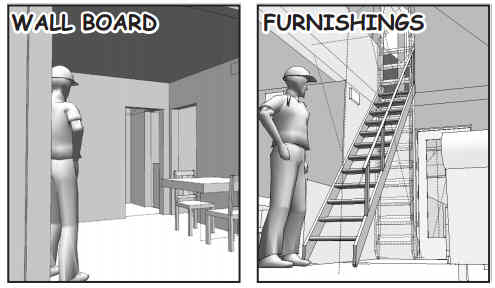

Modular cabinet design

Prefabricated cabinets reduce the cost of materials and installation. Their modular construction also makes it easier to coordinate their installation into the construction schedule.

Because the cabinets are finished on all sides, they can be uninstalled and rearranged as the kitchen and bathrooms evolve over the life of the house.

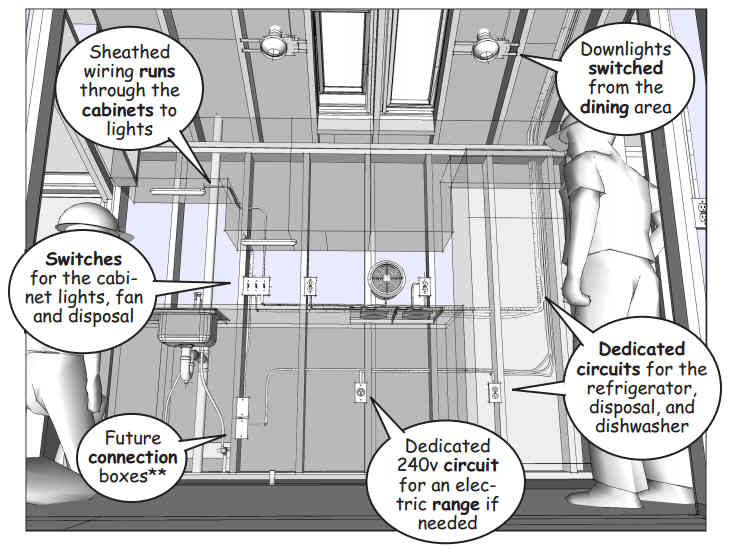

Note that countertops must be measured for sink cutouts, backsplashes, and other special features after the cabinets are installed. That means plumbing and electrical fixtures can’t be finalized or tested until the countertops are in place. . .

.

(To be continued…)

---------------------------

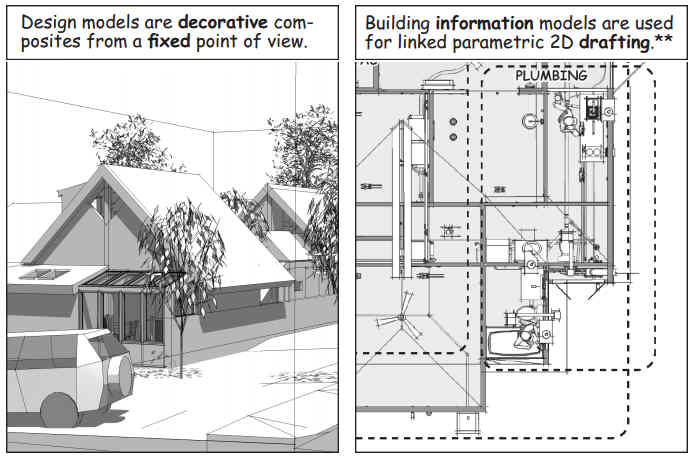

The material presented in this series has been taken from our book, “How a House is Built: With 3D Construction Models” The book includes annotated illustrations, captioned text, videos, models, and the 2D Preliminaries.

.

.