Myth 1: BIM is Easy

Many of those who think BIM modeling is easy to put into practice in a design or construction office have been blinded by the hype of clever marketing. The truth is, that other than standard (and colorful) objects like columns, beams, and simple gridlines, the real work of documenting a building’s construction is either quietly ignored or passed on to some unwitting subcontractor as part of a bid proposal.

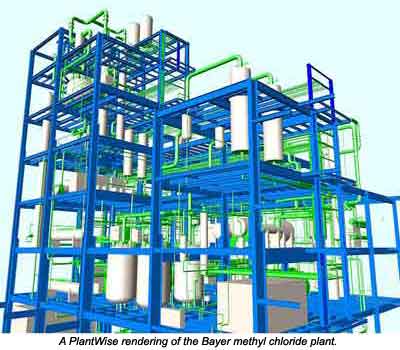

It also doesn’t take long to find that the hardware required to run a BIM program is well beyond the average desktop computer. In addition, the software is myopically tedious and labor intensive, requiring suites of specialized add-ons with mind boggling menus of objects as product placements. This complexity means any hope of successfully extracting information from a model requires a highly proficient operator, a lot of time and money, and a hands-on journeyman level of expertise in building systems installations.

Of course, the very idea of a collaborative approach to coordinating building systems is lost on project executives who have neither the time nor the practical knowledge necessary to teach a CAD operator how to build an installation exactly as it will be placed in the field. No BIM model can anticipate variables of cash flow, scheduling, weather, materials, and the availability of busy subcontractors.

In other words, except for the assembly of a straightforward structural frame or the combination of standard engineered equipment, any potential conflict or interference that might be detected by BIM software depends completely on the construction and modeling expertise of people who know little about bending, welding, or hanging the pieces of a building in the real-world.

Myth 2: BIM is Automatic

Unlike a machined part, a building is an assembly of diverse and interrelated pieces, separated by different trades, expertise, criteria, and rules of thumb. No amount of office collaboration will match the hour to hour decisions made by construction superintendents, foremen/women, and leads on the jobsite.

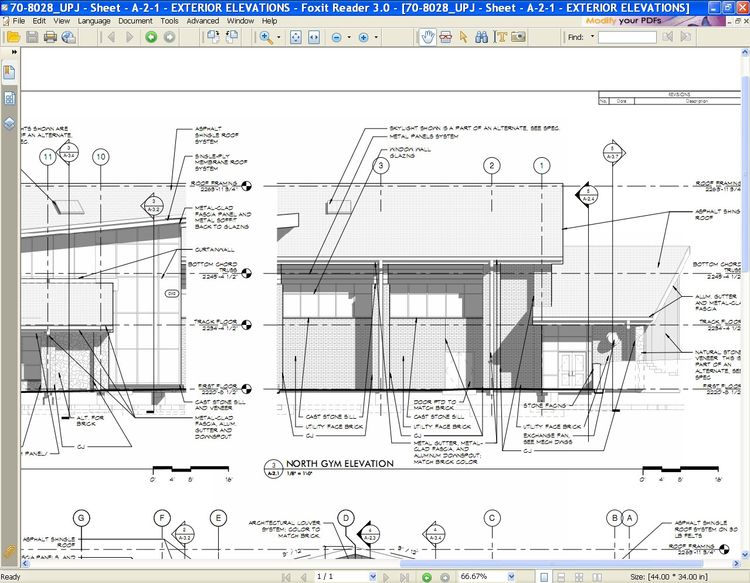

In the office, the quixotic challenge is to layer two and three-dimensional visual information into a BIM model, while coordinating cross references, sequencing output, and accommodating last minute changes. All with a constantly shifting team of isolated CAD operators. This means the very idea that a technician can simply extract a 2D construction drawing with a straightforward Export command, ignores the frustration that all too often accompanies almost every task that includes a computer. Something always seems to go wrong.

This means, the promise of BIM modeling requires technical skill to operate the software, construction skills necessary to build the model, drafting skills to pick up corrections and changes, and a mind numbing focus on the intricacies of layering useful information into the model’s construction. 2D output must then be manually plotted along with stock specifications and details into a well referenced set of paper-based documents and material lists.

To do this successfully, IT managers must also maintain the technology with constant upgrades, backups, repairs, comprehensive and continuous training, and a collection of proprietary tricks, key codes, and macros that work around long and often convoluted command structures.

Myth 3: BIM is Useful

And after all this extra work, the resulting model file is completely useless to long term facilities management after one or two generations of software upgrades. In fact, the very idea that a facility manager has the time, personnel, or budget, to keep up with the hardware and software necessary to use a BIM model stems from even more imaginative marketing.

First, because even the exact same workstations used to produce the exact BIM model is actually rapidly going out of date as the model is being built. In other words, once the model is finished, funded, put out to bid, and finally gets into the field as part of a contract, it has already been outdated by technical advances in the hardware and software. Everyone knows these programs are constantly evolving: debugged, tweaked, or abandoned simply to encourage sales of new versions. That’s a fundamental truth in the computer industry.

This means the “saved” files downloaded from the original equipment are nothing more than a volatile mix of soon to be antiquated media. Anyone who remembers a cartridge recorder, floppy disk drive, or zip-drive knows it’s just a matter of time before the data on CD/DVDs, hard-drives, solid state, and cloud storage will no longer be useful for future computer devices.

To some the solution may seem to be to keep early software purchases on older computers and maintain proficiency on backwater versions of the program.

But the personnel capable of operating these antiquated workstations efficiently are also volatile. First because a vacation, temporary assignment, or unemployment will reduces proficiency within weeks. In addition, competitive CAD technicians must job-hop to better software or workstations if they sense their current equipment is becoming out of date. They cannot afford to be left behind in a rapidly evolving industry. And those that do stick around are often burned out by boredom and dissatisfaction, having lost the will to keep pace with the treadmill because of years of utter frustration.

The Solution is Simple

The solution to the failures of BIM modeling is a 3D information management tool that does not require a lot of updates or changes, is free for the asking, and doesn’t require a CAD technician to operate. If communication and collaboration is the key to more efficient construction information modeling, what the construction industry needs is a simple, universal, and transparent 3D program that anyone can use on any computer. That’s Google SketchUp – which wouldn’t be FREE without Google.

Mark Carvalho, an early “voice” in 3D modeling software, once articulated a vision for SketchUp as a universal visual-communications tool; one that comes close to being the PDF of 3D modeling. His view was based on the philosophy of Brad Schell, the founder of SketchUp, and the original start-up team’s company motto: "3D for Everyone."

See The Daily CatchUp

Brad envisioned a software program that would match the feel and freedom of working with pen and paper using a simple interface, easy to learn, allowing people to play with ideas in three-dimensions after a few minutes of practice (See Wikipedia). In this way, models could be used to document constructions, simulate sequence and process, communicate alternatives, and be useful to anyone with the click of a mouse or a tap and pinch of the fingers.