Finish carpentry includes baseboards, chair rails, wainscoting, crown molding, shelving, cabinets and stairs. This kind of carpentry is not as physically rigorous as exterior construction and requires an entirely different set of tools and skills.

Stair construction

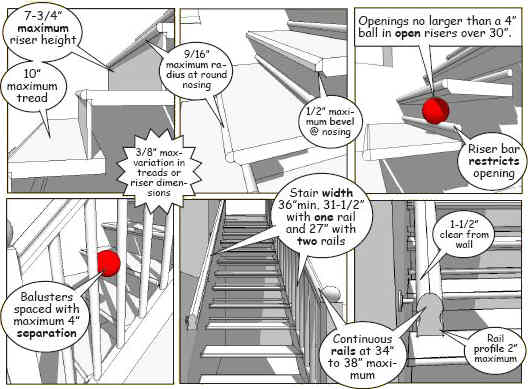

Interior work is not normally regulated by building codes. Exceptions include secondary structural installations, some types of materials, and hand and guard rails, balusters, and stair treads and risers (See Buzzwords).

The Stairway Manufacturers Association provides detailed guidelines for stair manufacturing, including general codes and standards.

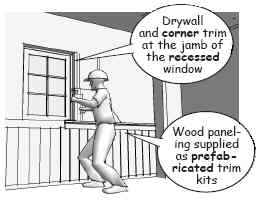

Prefabricated installations

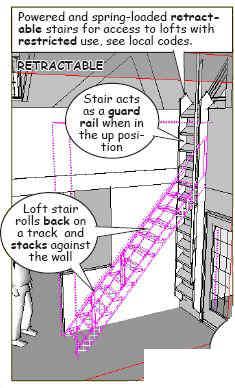

Access stairs that are required for upper floors are usually built into the structural framing and approved by the local building inspectors prior to issuing a building permit, but there are also prefabricated stairs for installation by finish carpenters and wood workers.

In this example, a prefabricated ships ladder is used to access the storage loft. The ladder is retractable and detailed on shop drawings for fabrication and installation. See websites similar to the Loft Centre for ideas and specifications.

If the loft is to be occupied and space is at a premium, a circular stair is a good alternative to the ships ladder.

Circular stairs are designed to meet all code requirements and are cut and assembled on site by metal fabricators to match field dimensions.

Efficient design

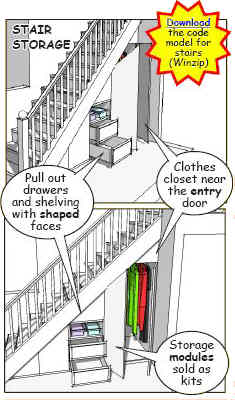

The value of interior designers as opposed to building designers is that they find ways to increase the efficiency of a given space. For example, the space under a stair can be used for storage.

But the installation of special features such as these must conform to local building codes. In this example, if there is not an alternate exit from the upper floor, built-in storage under the stair may be rejected as a fire hazard. . .

(To be continued…)

---------------------------

The material presented in this series has been taken from our book, “How a House is Built: With 3D Construction Models” The book includes annotated illustrations, captioned text, videos, models, and the 2D Preliminaries.

.

.